TOOLING Expertise

EXPERTISE

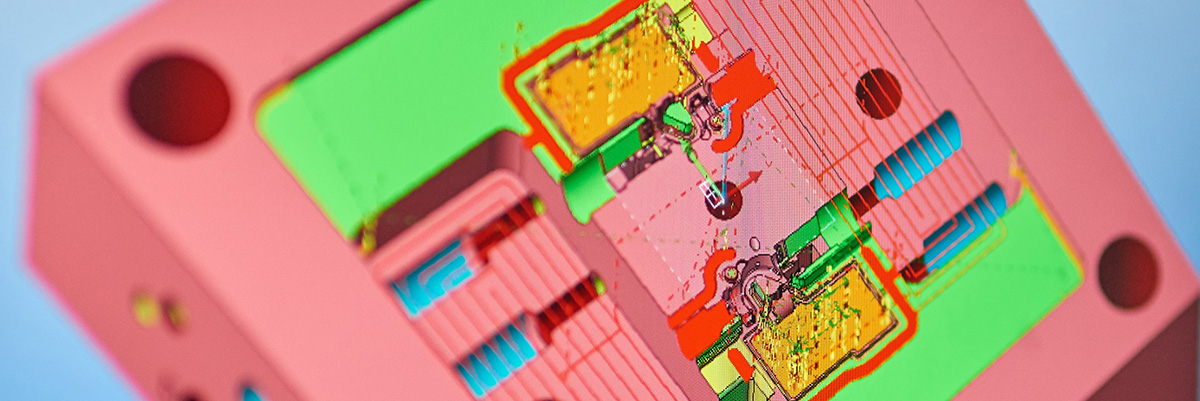

CAD and CAM by VisiCAD®

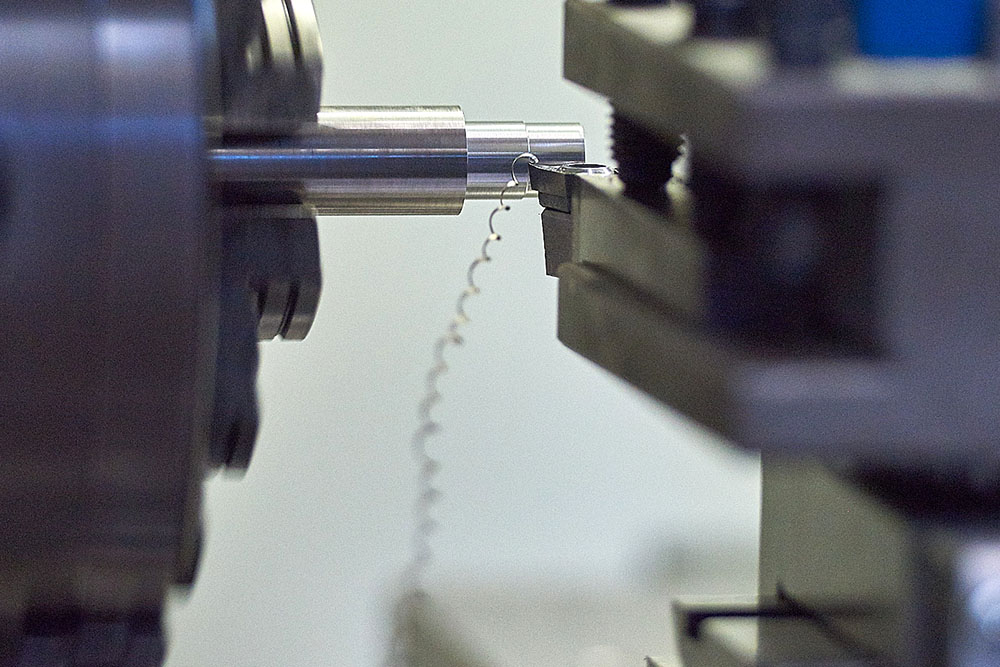

Precision combined with quickness and flexibility is a critical success factor for Amper-Plastik. The fully-integrated CAD/CAM software VisiCAD® allows a smooth production flow between engineering and tooling department. Data losses and delays at software interfaces are eliminated – development and manufacturing times shortened.

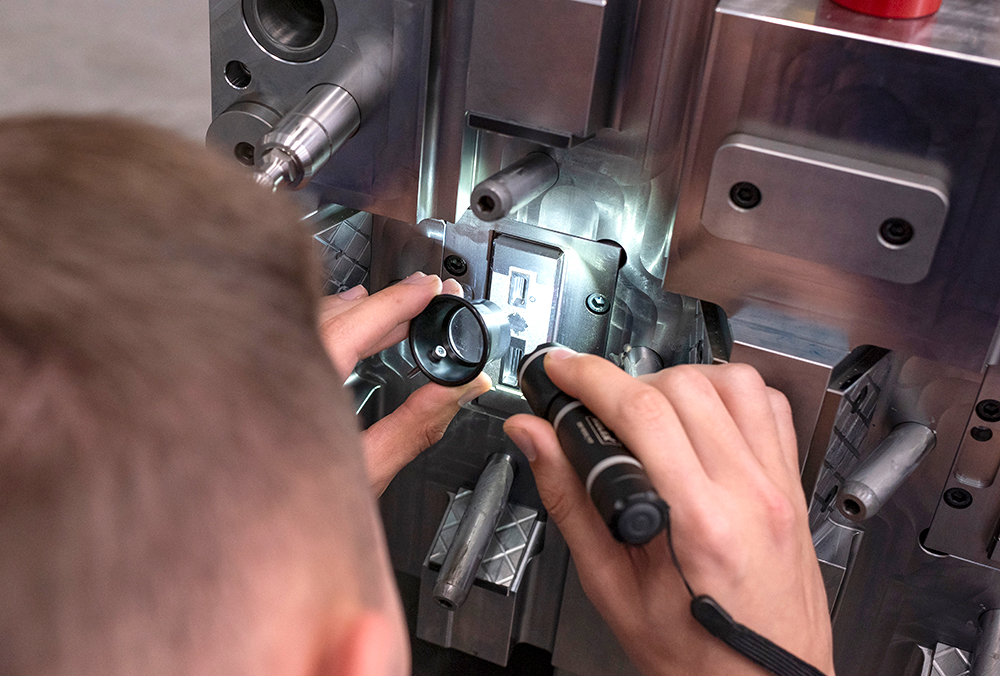

Prototype and Small-Series Tools

Another corner stone of our success story: We develop and manufacture prototype tools in-house. Therefore samples are earlier at hand and can be used for design finalization or test purposes – all of course on schedule and in the quality you require.

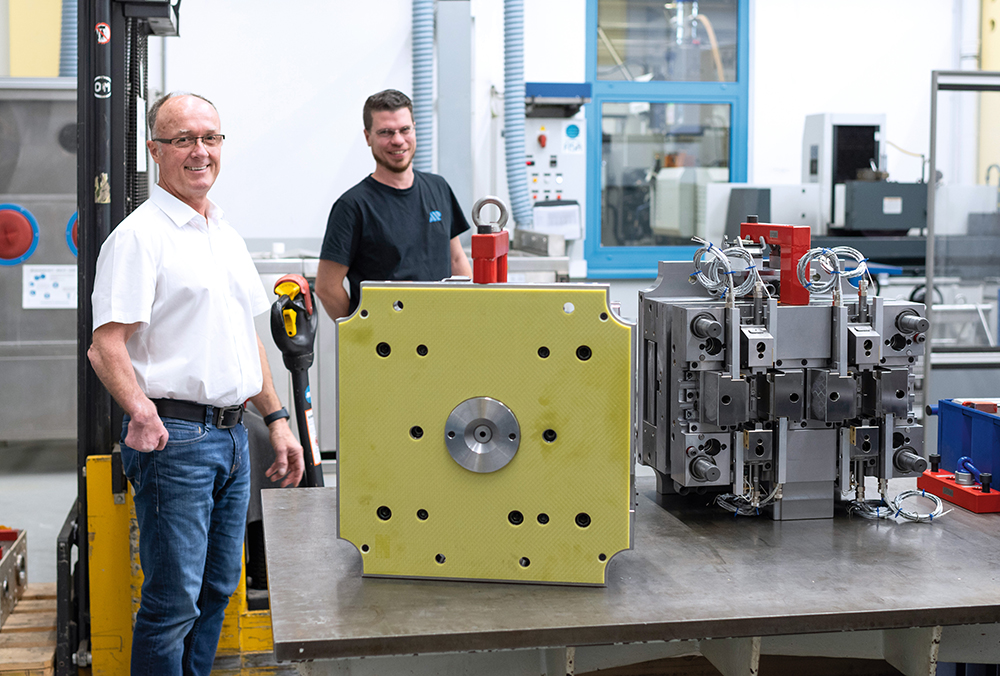

Flexible Manufacturing and Modification of Precision Tools

Development work and tooling hand-in-hand: Frequently changing market requirements make tool modifications our daily business. Thanks to our internal toolroom we are able to react quickly and implement changes in short time.

Jigmaking and Automation Engineering

In the assembling, testing and automated manufacturing of plastic parts customized jigs and fixtures are required. These are developed and manufactured in-house by a cross-functional team. This saves time and costs.

Accredited Education and Training

As you know: Experienced specialists are a scarce resource. Therefore we use a concerted approach to develop our own personnel and offer formal training in recognized occupations, like e.g. mould making. The result is a well-balanced tooling team with experienced and skilled manual workers as well as younger colleagues well versed in programming and the digital world. An at all hands effective organisation.