AMPER-PLASTIK Quality

Menu "AMPER-PLASTIK"

Quality Management

Amper-Plastik manufactures quality products. We inspire, not just satisfy our customers. Our well-established quality management system is DIN EN ISO 9001 certified since 1997 already. This is one of the reasons why we look back on long-lived customer relations and partnerships. And recent awards like having been ranked TOP-5 in the category ”Quality“ among all Siemens suppliers world-wide are another incentive for our continued efforts.

Technically mature quality management system DIN EN ISO 9001 certified since 1997.

A well-established system you may rely on.

UL- accreditation since 1989 (Underwriters Laboratories).

This universal standard for product safety and fire protection is applicable for almost all electronic devices. Tested for safety, playing it safe.

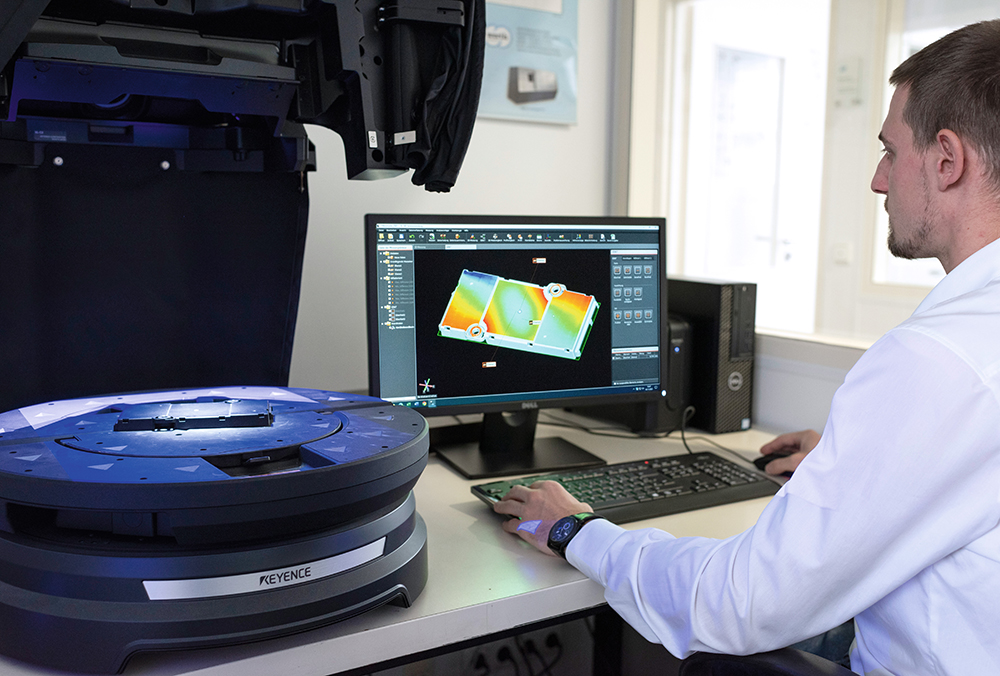

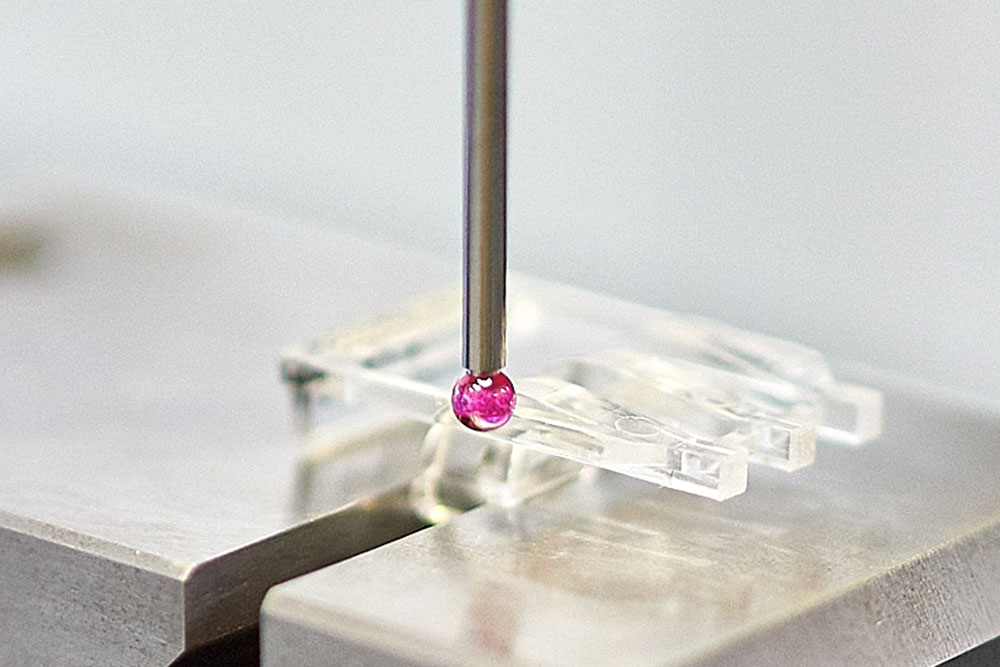

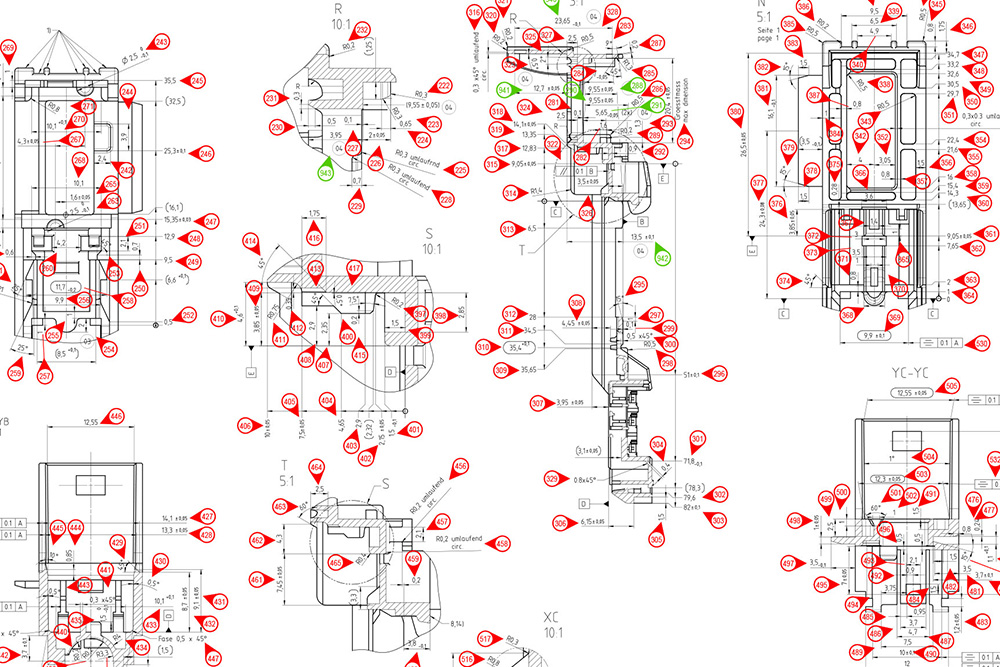

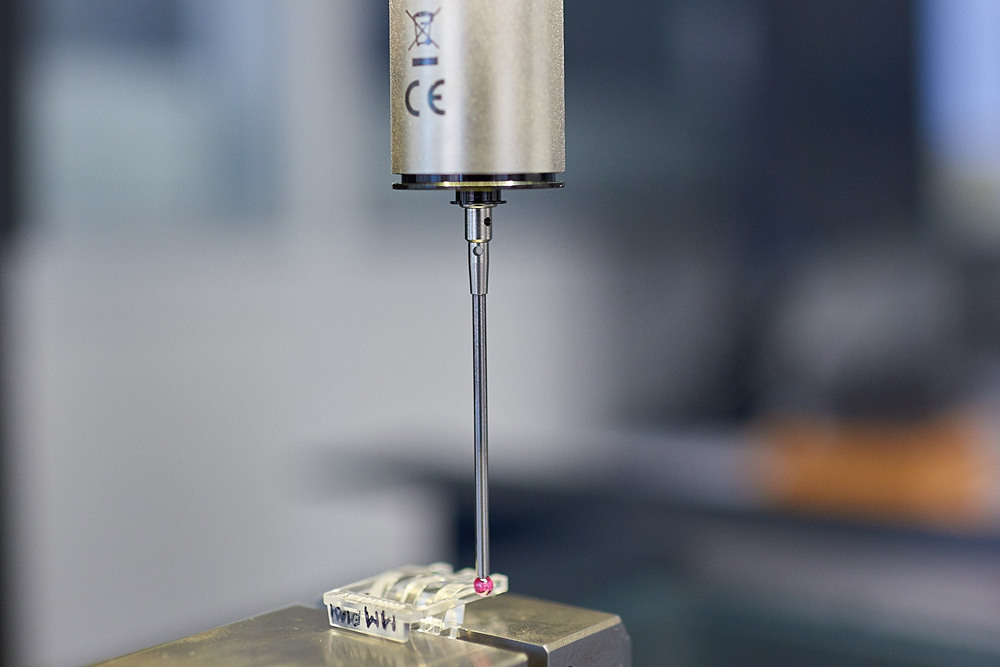

Measurement and test reports based on CNC-controlled measuring equipment - CT, video and tactile testing.

For trust is good, control is better.

Real-time quality control in climatised rooms within the three-shift model.

Quality controls twenty-four-seven – so you may rest assured.

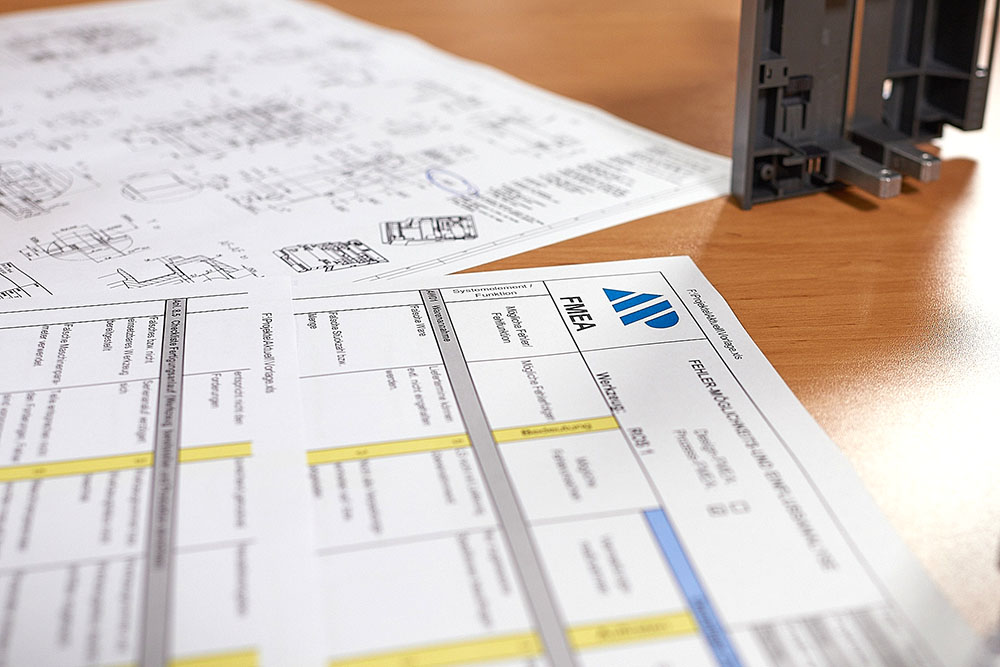

Evolved CAQ-system according to DIN EN ISO 9001.

Computerised and accredited quality assurance, a zero defect culture.

Melt flow, residual moisture, and ignition residue tests mandatory for all polymers.

So you won’t face troubles afterwards.

Roughness measurement, tensile and compression tests as well as visual colorimetry on finished parts

For superior products.