Injection Moulding

TRENDSETTING INJECTION MOULDING SOLUTIONS

Amper-Plastik is well-equipped to manufacture trendsetting injection moulding products of all kinds of thermoplastic and elastomer resins. With our modern production site, a high-tech machine outfit, innovative production technologies and our competent and experienced team we prove our capabilities from day to day. And “Industry 4.0” for us is not just a buzzword, but has been implemented deeply in our processes, which are already digitized to a great extend.

Manufacturing Premises

Sufficient space and continued modernisation are key to the highest quality levels in production. Since 2014 we have doubled the production area of our injection workshop to 2,140 sqm and have subsequently continuously invested in a modern infrastructure. Sensor-controlled LED light, dark emitters as heating units, a heat recovery plant and thermal insulation of our office building do not only improve the occupational conditions at Amper-Plastik, but are also our contribution to environmental protection.

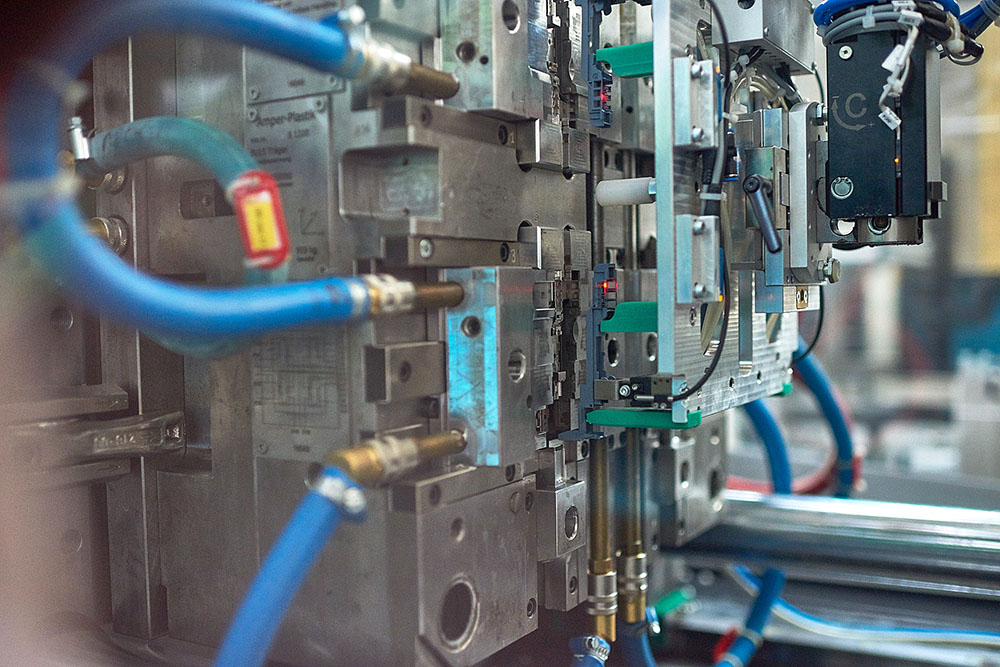

Machinery in Operation

Our machine outfit is continuously extended and moderised. Apart from reliable hydraulic presses we are increasingly utilizing fully-electric injection moulding machines. These have an increased repeat accuracy, save energy, and emit less heat and noise. Thereby electric machines are beneficial for the working environment and the product quality at the same time. We cover a wide range of plastic components from a net weight of 0.2 gr. up to 1.5 kg on our machines with 150 to 5,000 kN clamping pressure. And with an increasing level of automation – for instance by in-process packaging of the articles in the manufacturing cell – we economically handle large-scale volumes.

The Team

Longtime experience, evolved knowhow, and loyalty to the company characterize our staff. Many colleagues in key positions as for instance in plant, production and quality management can look back on more than 30 successful years with Amper-Plastik. Quality, flexibility and reliability are our standard and are delivered everyday. This applies from first-of-tool samples to assembly groups with automated quality inspection in a large-scale production – at all times performed and monitored by our experienced professionals in an efficient three shift model.

Manufacturing Technology

Precision matters! The accuracy of our precision moulding allows tolerances of down to ± 0.03 mm in serial conditions. We rely on multi cavity tools in mass production. As an example up to 105 different push-buttons are generated during each moulding cycle and are directly assembled in the upper shell of a professional keyboard. Some applications require two-component moulding. We apply this technology for all suitable material pairings, hard-hard, hard-soft or soft-soft and with an article weight of up to 1 kg. In modern sensors and connectors available space is very limited. We meet this requirement by thin-wall moulding. Structural components with a wall thickness of only 0.4 mm are therefore not uncommon in our product portfolio. Further core areas of our expertise are insert mouldings, high-gloss surfaces, optical parts and light conductors. Summing up our manufacturing technology and experience allow us to realise almost any of your ideas for precision parts at the highest quality standard and very cost effectively.

Resources and Material Supply

As a leader in injection technology we do not just witness global trends but are among the first companies to implement innovations within our industry. This applies for instance for the substitution of metal parts by plastic components, since weight reduction and cost optimization are a major topics not only in the field of mobility. But the origin for processing is always the best possible plastic material for your application. Therefore we work with all common grades of thermoplastic and elastomer resins. Even high-performance polymers like PEEK, LCP, PPSU or PPU are found within the range of our products. Additionally we process renewable primary producs - Wood-Plastic-Composites (WPC) are the keyword in this field. Before being processed by our machines the raw materials are conditioned by our central computer-controlled predrying station. Thus we can guarantee reliable and energy efficient resin processing. And we control the residual moisture of the raw material before each production lot – a time-consuming test, but irremissible for the mechanical and visual properties of the finished goods.