INJECTION MOULDING Components

THE WAY FROM CONCEPT TO PRODUCT

Simple draft or detailed technical drawing, mere description of the application or mature requirement profile – in each case we will gladly support your design ideas for plastic components from the early concept phase. Even a complete article’s development according to specifications is not uncommon within our development department. In each case the technical feasibility of the component in the context of injection process, moulding tool and a suitable polymer is key to success. With our evolved know-how we ensure a reliable production of all parts within an economical manufacturing concept, tailored to the demand quantity.

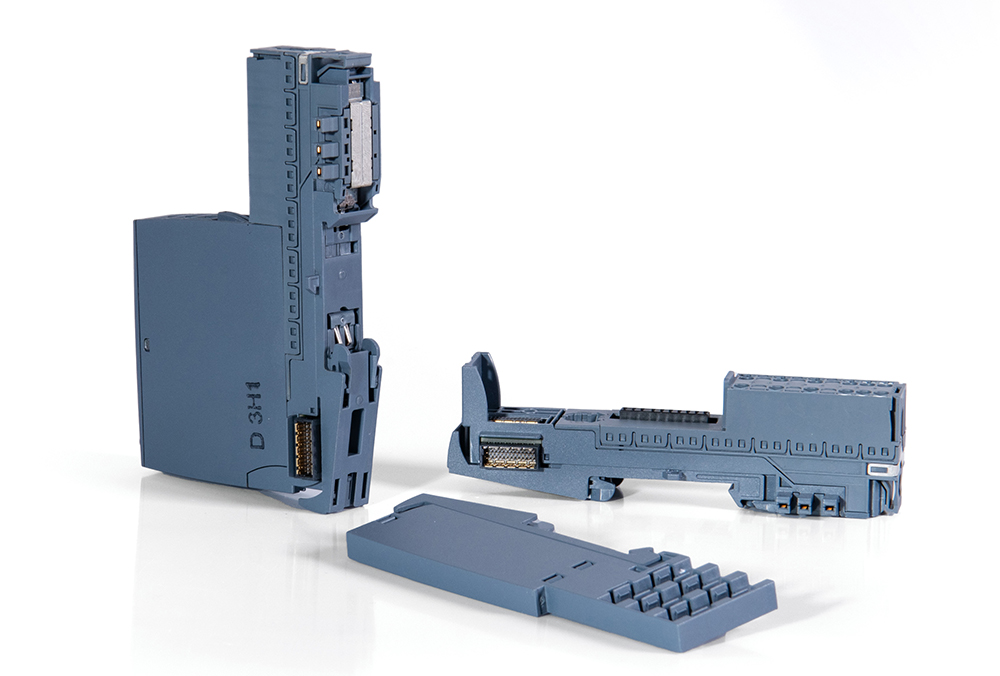

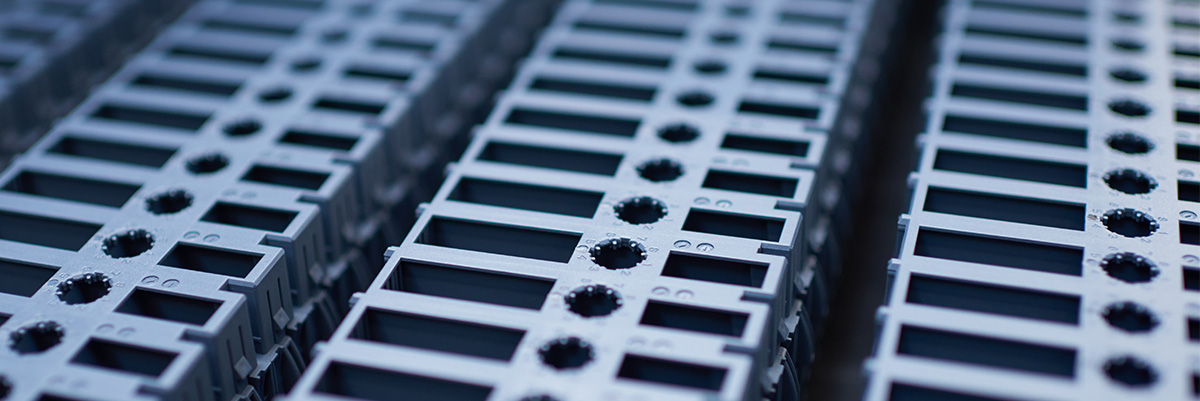

Technical Plastic Components

Regardless whether it is utilized in a machine, an automobile or inside a technical device – modern moulded parts have to stand up to an environment of sometimes extreme mechanical, thermal and chemical conditions - And comply with narrow dimensional tolerances. The development, manufacturing and finishing of these highly specialized goods is our profession - starting from small series to eight-figure annual quantities.

Special Applications

A constant trend in plastics processing is the development or more and more complex components. Therefore our portfolio includes techniques like two-component moulding for hard-hard, hard-soft or soft-soft material pairings, or insert moulding. Furthermore we have gained long-term experience with transparent parts and optical components. Whenever most demanding requirements necessitate the use of high-performance polymers we are also up to the task.

Zero Defect Approach

Safety relevant products with a zero defect target require continuous process monitoring. Therefore we control every single one of these articles for certain defect characteristics. Either already within the injection process by pressure or heat sensors or by means of cameras or control jigs once the goods are finished. These techniques belong to the daily business of Amper-Plastik and became part of our quality culture.