BRANCHEN

MADE IN GERMANY.

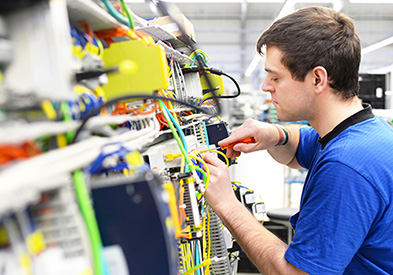

“Made in Germany” is a label for quality and technical know-how in the field of machine building. This is proven by the leading position of German mechanical engineering. As a reliable and innovative technology venture Amper-Plastik contributes to the top ranking to a substantial degree.

Keyword: Drive and control systems. Each moving component in a machine requires a drive and a control unit. And in both of them you will find innumerable plastic components made by Amper-Plastik, all over the world. Coil bodies in electric motors made by precision moulded high-performance polymers are an example, withstanding the extreme mechanical, thermal and chemical stresses. Or premium housing components for the control units of the latest generation, which are another important factor for the machine makers in order to consolidate their market position.

Amper-Plastik is part of the engineering family and manufactures is products with machines, that often contain the own injection-moulded components. Thereby the closed loop is created. And we are proud of being regularly awarded for the quality and reliability we are providing within the industry.

customer

Testimonials

We offer technically sophisticated solutions and services for optimizing production and producs – especially for automation processes. And the same we claim within our supplier base. Open communication with competent specialists at eye level and the reliable supply of high-quality components at any time are key factors. With Amper-Plastik we are having this kind of cooperative partnership in the field of injection moulded components - already for many years. As the expression goes: Can you recommend this company: Yes, I can. Without any reservation.

Oliver Baier

Heitec

„Since 2015 our GETT Gerätetechnik GmbH has been enjoying a reliable and ever-growing partnership with Amper-Plastik (AP). The complementing portfolios play an important part for the mutual and continuous expansion of our relationship, as AP is benefiting from GETT’s product expertise in foil covered keyboards while GETT is being provided with APs high-quality injection moulded products. One of the most recent success stories started in the year 2020 in a difficult market environment, in which close teamwork between both organizations made the knowledge-driven development of state-of-the-art human machine interfaces for individual end-consumers possible. In a nutshell, we value Amper-Plastik‘s outstanding quality performances and its professional service in our long-standing customer-supplier relationship. We are looking forward to work together on more upcoming projects.”

Candy Döring

Gett-Group